Orchestrate Every Aisle, Without Writing Code

From Disarray to Harmony Across Sites

Design the Location Model Visually

Hierarchies That Fit Your Reality

Attributes Drive Smarter Decisions

Operational Automation Without Code

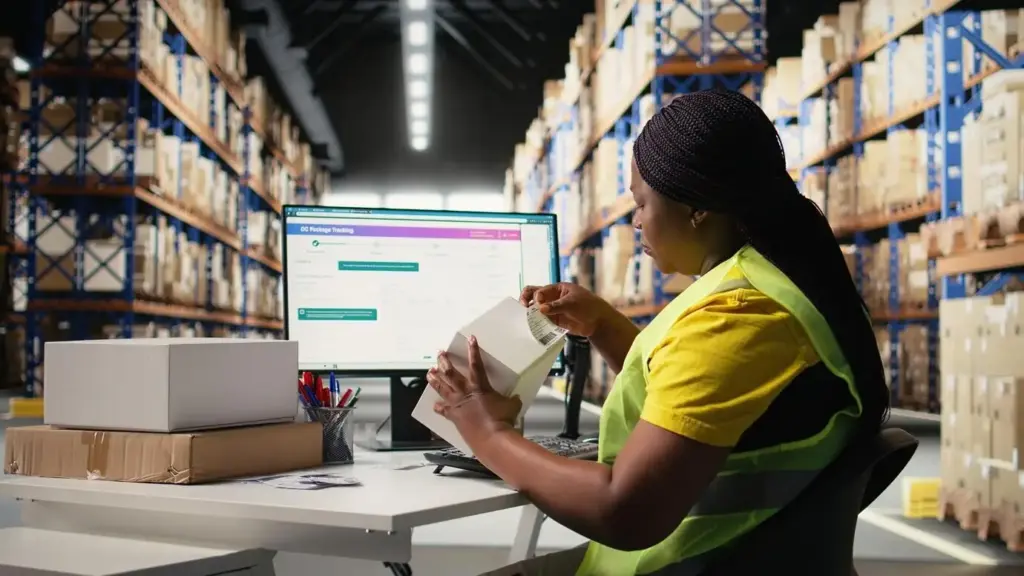

Drag-and-Drop Workflows for Daily Rhythm

Compose flows that begin with clear triggers, branch on conditions, and assign mobile-friendly tasks. For example, if a pallet lands in an over-height bay, route a task to maintenance and suggest an alternate putaway. If fast movers hit a minimum, schedule replenishment with travel-optimized sequence. These flows document the best way to work and make it the easy way to work, ensuring consistency across shifts and sites without demanding a single line of custom code.

Validations That Prevent Expensive Mistakes

Use readable rules to stop errors before they cost time or damage product. Block overweight pallets from light-duty levels, reject incompatible chemicals near food, and warn when ambient goods approach freezer boundaries. Add barcode and dimension checks to catch mismatched master data. Each validation leaves a friendly breadcrumb explaining what happened, helping teams learn without blame. The payoff is quieter operations, fewer investigations, and growing trust that the system will flag problems early and clearly.

Notifications and Escalations That Reach People

Alert the right person in the right channel—mobile, email, chat—when capacity thresholds hit or doors back up. If a task goes stale, escalate to a lead with context and suggested actions. Quiet periods remain quiet, but rising risk becomes visible quickly. Clear, timely nudges keep crews focused, promote accountability, and reduce firefighting. Over time, these signals become a shared language that aligns facilities, carriers, and planners without marathon calls or cryptic dashboards nobody checks.

Integrations, Data, and Analytics

Change Management, Onboarding, and Real Stories

All Rights Reserved.